Revolutionizing Large-Scale Manufacturing with 3D Printed Molds

In the ever-evolving landscape of large-scale manufacturing, thermoforming stands out as a versatile and cost-effective process for creating complex components across industries like automotive, aerospace, marine manufacturing, and theme parks. However, traditional tooling for thermoforming, especially for large parts, is fraught with challenges—prolonged production times, high costs, and limited design flexibility often hinder efficiency and innovation.

Massivit’s advanced 3D printing technology offers a transformative solution to these challenges. Using its automated process, manufacturers can produce thermoforming molds rapidly, cost-effectively, and with unparalleled precision. This breakthrough enables the creation of complex, customized designs while reducing waste, labor, and lead times.

Meeting the Demands of Industries that Think Big

Large-scale industries such as aerospace, automotive, marine manufacturing, and theme parks rely heavily on thermoforming to create durable, lightweight, and high-quality components. In the aerospace sector, thermoforming is instrumental in producing aircraft interior panels, bulkheads, and seating components that must meet stringent performance standards. Similarly, in the automotive industry, elements like dashboards and bumpers demand precision and durability to ensure safety and aesthetic appeal. Marine manufacturers require molds capable of crafting intricate interior panels and robust hull details for yachts, while theme parks depend on large molds to shape scenic elements and ride components that can withstand significant wear and environmental exposure.

Producing these large molds with traditional methods often involves excessive material waste, extended timelines, and high costs. By leveraging advanced 3D printing technology, manufacturers can now meet the unique demands of these industries, delivering molds that combine durability, efficiency, and design flexibility at an unprecedented scale.

Challenges with Traditional Large-Scale Molds

Creating large-scale molds using traditional methods, such as aluminum casting or composite materials, presents significant challenges in terms of time, cost, and flexibility. The manufacturing process for aluminum molds, for instance, often involves extensive machining and finishing, which can take several weeks or even months to complete. These extended timelines can disrupt production cycles, delaying the delivery of critical components across industries.

In addition to the time investment, the costs associated with traditional mold production are substantial, often making short-run production economically unfeasible. Furthermore, traditional methods impose inherent limitations on design flexibility. Complex geometries, fine details, or intricate features that might enhance the functionality or aesthetics of a part are often difficult, if not impossible, to achieve without significantly increasing production costs and time. These challenges underscore the need for innovative approaches that can streamline mold production without compromising quality or creativity.

Massivit’s 3D Printing Solution

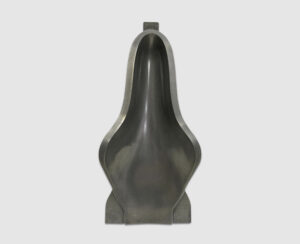

Gel Dispensing Printing (GDP) technology redefines the production of large-scale components and prototypes, offering a revolutionary solution to the challenges posed by traditional manufacturing. In addition, the company’s Cast In Motion (CIM) process enables the creation of massive molds with intricate design details in a fraction of the time required by conventional tooling methods—days instead of weeks or months.

For example, in the aerospace sector, ACS Hybrid Inc. utilized Massivit’s technology to produce thermoforming molds for aircraft components, achieving unparalleled efficiency and quality. The automotive, trucking and marine sectors benefit from custom-designed, durable molds for thermoformed components or carbon parts, meeting the high standards of modern vehicle design.

Why Industries are Switching Technology

Massivit’s 3D printing technology is rapidly becoming the go-to solution for industries requiring large-scale molds, offering unparalleled advantages over traditional methods.

- Speed: drastically reduces production timelines, enabling molds to be created in just days rather than weeks or months, ensuring faster time-to-market.

- Cost-Effectiveness: By eliminating the need for expensive materials and lengthy processes, significantly lowers costs for short- and medium-run production.

- Design Freedom: The ability to produce complex geometries and intricate details that are challenging for conventional tooling unlocks new creative possibilities for designers and engineers.

- Scalability: Massivit’s technology easily adapts to varying production demands, whether for low- or high-volume manufacturing, offering unmatched flexibility.

- Sustainability: The process minimizes material waste and reduces energy consumption, aligning with industry goals for eco-friendly manufacturing.

Conclusion: The Big Advantage of Thinking Big

revolutionizing large-scale thermoforming by delivering faster, more cost-effective, and sustainable solutions for industries that demand precision and innovation. With its ability to produce massive, intricate molds in record time, Massivit empowers businesses to think bigger and achieve more.

Ready to take your production to the next level? Discover how Massivit can transform your manufacturing process today.